Manual Top Discharge

Bag Lifting Type

Bottom Discharge

Laboratory / Trolley Mounted

Full Body Opening

Manual Top Discharge

Spindle Type for Cone / Cheese Drying

Hydro Extractor with Fabric Loading / Unloading Device

Cake Lifting Hydro Extractor

Tow Carrier Lifting Hydro Extractor Machine

|

We make use of advanced production techniques and hi-tech equipment that are installed at our well-developed manufacturing unit. We manufacture Compression Molding Press, C type Press, H Frame Press, Fitting Press, Lab Testing Press etc. We also manufacture the hydraulic press machine as per customer specific requirements. Our hydraulic pressed are working successfully in many industries. We have exported our machines to Bangladesh, Sri Lanka, Nepal, Middle East and Africa.

Cotton Waste

We are offering this type of cotton waste baling press machine in 45-75-100-150 ton capacity, which is specifically designed for 50 kg to 250kg bale. These machines are provided with mechanical bale ejector as option that helps in easy bale ejection. We also provide hydraulic door locking system for easy operation.

Capacity: 45-75-100-150-200 Ton

Bale Weight: 50 Kg to 250 Kg

Applications: Cotton Waste, Cotton Yarn, Yarn Waste, Wool, Woolen Yarn, Synthetic Yarn, Synthetic Fibre, Jute etc.

Pet Bottles Machine

We offer pet bottles baling machine mostly in two ranges 50-60 bale and 100-130 kg bale. Capacity of the pet bottle baling press is 25 ton and 50 ton. Our many customers use this machine to press the pet bottles and make very good profit on that.

Capacity: 25 Ton & 50 Ton

Bale Weight: 50 Kg to 130 Kg

We also make customized baling press for 150 kg to 200 kg bale.

Applications: Pet Bottles, Water Bottles, Plastic Waste etc

Specifications:

• Crompton Greaves / Siemens make motor

• Yuken make valves

• Yuken/ Denison make pump

• Heavy Duty Structure

Optional

• Hydraulic Bale Ejecting System

• Hydraulic Door Locking System

DMW offers Raising Machines traditionally excellent in quality with Guarantee of performance High level precision, low breakdown and low maintenance are the promised salient features of our product. A universal Double Action wire Raising Machine comprising pile and counter pile Raising Rollers. It can process all types of textile knits or woven, either natural or synthetic textures.

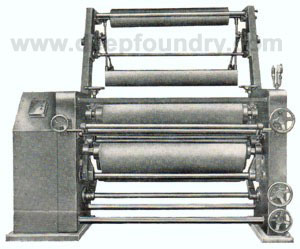

DMW Heavy Duty Single and Double Bed Rotary Press Machine is suitable for Textile Processing Housing for continuing pressing of the cloth

Main Rollers:

The main roller of the machine is made of graded cast iron and precisely machined for the good quality output.

Bed:

Upper bed plate stands on four C.I. pillars fitted with M.S. bolts 1½” dia. Bottom plate stands on three hydraulic plungers.

Entry and Exit:

Entry of the fabric is through swivel tension adjusted after passing through the steam damping roller and brushing roller fixed on the front of the machine. The fabric exit is by the plating down device.

| Model | Unit |

D-72 | D-72S | D-84 |

D-105 |

| Width of Main Roller | Inches |

72 |

72 |

84 |

105 |

| Dia. of Main Roller | Inches |

18 |

26 |

22 |

18 |

| Hydraulic Pump Pressure | Lbs. |

1000 |

1000 |

1000 |

1000 |

| Hydraulic Plungers | Nos. |

3 |

3 |

3 |

5 |

| Weight of Machine |

Kgs. |

5500 |

7000 |

7500 |

7500 |

| Production | Mts / min |

15 |

26 |

20 |

15 |

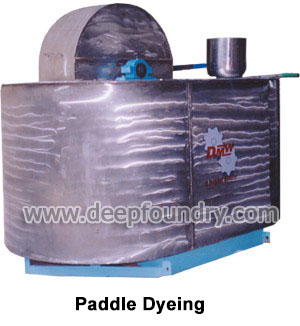

Paddle Dyeing Machine is used in industry for bleaching, scouring and dyeing of Hosiery, Garments, Rugs, Bed Spreads, Bath Mats, Blankets, Sweaters and any piece goods. Paddle Dyeing gives the quality finish and uniformity. Salient Features :

Capacity :5 Kg to 25 Kg |

|

| Frame Cast Iron Frames of fabricated from M.S. Plate M.S. Section with cross section strengthening bars. Main Cyclinder: Hollow Pipe made of 12 mm thick M.S. PLATE OF 20’ Dia and 62” width Property ground and well polished moving on ball bearing with steam inlet and outlet device. Pressing Rolls: One is placed at top and one placed in front, made of M.Steel 6½ Dia and 62” width well polished and moving on ball bearing. Felt Centgering & Tightening: One Felt Centring Roller and one Felt tension adjuster are provided, which are moving on ball bearings. |

|

| Working Width | 60” (1525 mm) or 72” (1829 mm) |

| Electric Load | 3 H.P. or 5 HP ( 1440 RPM) |

| Steam Pressure | 25 to 50 PSI |

| Dimensions | Height 8’ 8”x width 9’xLength 9’ (2645 x 2745 x 2745 mm) |

| Weight | 3000 Kgs. |

| Production | 8000 to 12000 meters |

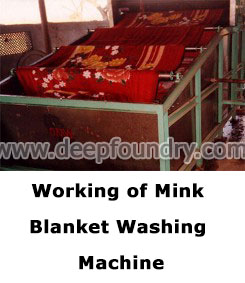

| This machine helps in removing the excess dye, glue, and other contaminants i.e. oil, dust etc. from the blankets/fabric by squeezing the blanket through two special rubber rollers and then rising again in the stainless steel tank. Specifications: Working Size : 96” (2450mm) Machine Size : Width 8½ Feet (2590mm) x Height 8 Ft (2450mm) x Length 15½ Feet (4725mm) Washing Capacity : 100 double bed blankets / 150 single bed blankets Power Consumption : 5.5 Kw./ Ø3 / 415V Water Consumption : Minimum 35 Lt. / 1 Sheet. |

|

| We have added Hydraulic Fibre Pressing Machine to our product range. This machine is very suitable for

making fibre cakes of cotton, acrylic and polyester of high density.

The heavy Duty Hydraulic Cylinder exerts pressure of 25 Ton to 100 Ton depending on the density

required for the cake. Working Principle The loose fibre / tow are fed to carrier through chute / feeding device, which rotates at slow speed through VFD. After filling the carrier, Hydraulic Cylinder Presses the loose fibres / tow into dense cake required for dyeing. The cantilever arm rotates 180 o towards 2 nd Carrier to press the fibre. Hence large production is achieved in double drum machine. |

|

| Cantilever structure is made of SS304 Section Pipe, I-Beam for corrosion free working for the years to come. |

| Cantilever rotates on heavy duty Pillar with 3 bearings. |

| SS304 carrier rotates on turning table provided with 3 HP Motor / Gear Box. |

| Carrier RPM can be changed very easily by VFD for ease of operation. |

| Hydraulic Cylinders have 4 guide rods with brass bush for efficient working. |

| Full Electronic Panel with PLC is housed in SS304 Panel Box with all the safety interlocking. |

| Dia of Carrier | 1000mm, 1220 mm, 1525mm and any carrier according to size. |

||||

| Stroke of Cylinder | 600mm, 725mm, 1000 mm. Single and Double Drum |

||||

|

220-235 Kg/m 3 | ||||

| 350-390 Kg/m 3 | |||||

| 325-335 kg/m 3 |

|

Deep Foundry & Mech works- Manufacturers and supplier of Zero Hold up sparkler filter in India that is made up of high quality stainless steel having customized finished design. The cartridge assembly consists of plates, perforated screens, spacres and filter media stands on S.S trolley. The whole assembly complete with attached pump and pipe lines through welding.

|

|

Type |

Dia |

No. of Plates |

Filtering area (m2) |

Cake capacity |

Output |

DMW86 |

8” |

6 |

0.198 |

4.50 |

400 |

DMW88 |

8” |

8 |

0.254 |

5.78 |

500 |

DMW148 |

14” |

8 |

0.756 |

27.00 |

1500 |

DMW1410 |

14” |

10 |

0.924 |

35.00 |

1800 |

DMW188 |

18” D |

8 |

1.270 |

51.00 |

2500 |

DMW1815 |

18” S |

15 |

2.270 |

44.00 |

4500 |

DMW1812 |

18” D |

12 |

1.840 |

78.00 |

3700 |

DMW1823 |

18” S |

23 |

3.400 |

65.00 |

6800 |

DMW2412 |

24” D |

12 |

3.430 |

148.00 |

6700 |

DMW2423 |

24” S |

23 |

6.336 |

120.00 |

12600 |

DMW337 |

33” D |

7 |

4.000 |

175.00 |

8000 |

DMW3314 |

33” S |

14 |

7.500 |

210.00 |

15000 |