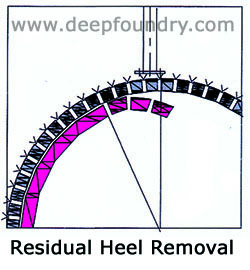

Manual Top Discharge Centrifuges (3 Point / 4 Point)One of the simplest types of centrifuge widely used in the industry. The solid Material is removed out manually from the top of the centrifuge.General Features : Speed Control through VFD. Half lid open (Manual / Hydraulic) Dynamic Braking Optional Features : Fully opened outer case for better accessibility for cleaning & maintenance Nitrogen Blanketing Zero speed interlock Vibration sensor Cleaning-in-place (CIP) Sizes : Basket dia 12” to 75” (300 mm to 1900 mm) Basket height 6” to 48” (150 mm to 1220 mm) Capacity : From 10 Kgs to 1400 Kgs / Batch Optional features for all sizes & models Zero Speed Interlock Cleaning in Place (CIP) Vibration Monitoring Full body opening Cake thickness sensor Nitrogen blanketing PLC Controlled Operations Residual Heel Removal |

|

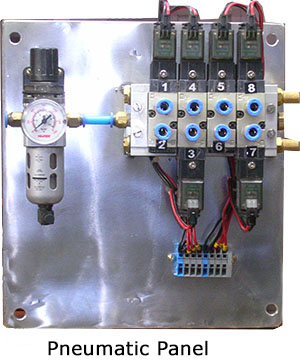

Bag Lifting CentrifugeThese are instant Top Discharge Centrifuges in which Filter Bag is fitted in the basket having easy detachable top ring. The filter bag along with top ring is lifted by Hydraulic Device or hoist and moved to desired place for unloading, by opening the centre of the filter bag.General Features : Full lid opening by Hydraulic / Pneumatic cylinder Speed control through VFD. 4 Point Visco Damper cGMP Construction Optional Feature Full opening outer case for better cleaning & maintenance Nitrogen Blanketing Vibration sensor CIP Hydraulic Loading / Unloading device PLC Controlled Panel Sizes : Basket dia 36” to 74” (915 mm to 1900 mm) Basket height 18” to 48” (457 mm to 1220 mm) Material of Construction / lining SS 304, 316 L, 904 L, Hastealloy Carbon Steel , Rubber Lining, Halar (ECTFE) / Tefzel (ETFE) & Teflon (PFA) Optional features for all sizes & models Zero Speed Interlock Cleaning in Place (CIP) Vibration Monitoring Full body opening Cake thickness sensor Nitrogen blanketing PLC Controlled Operations Residual Heel Removal |

|

Bottom Discharge Centrifuge with ScrapperThe process of filtration is similar to other types of centrifuges the difference being in the method of unloading the solids. The scraper cuts the solid cake while the Basket is routing at a slow speed. The solids are discharged through openings provided in the Basket bottom and Bottom Base / Inertia plate.General Features Solid Discharge Side / single port discharge with sweeper on basket. Large Central opening Drive Variable frequency Drive (Inverter) Lid Opening Partial Half lid opening Fully opening outer case Scraper Mechanism Motorised Hydraulic Manual Cake Monitoring Mechanical Cake Thickness Censor Ultrasonic Sensors Available Sizes Basket dia : 36” (915 mm) to 72” (1800 mm) Basket height : 20” (510 mm) to 30” (765 mm) Special sizes can be designed Optional features for all sizes & models Zero Speed Interlock Cleaning in Place (CIP) Vibration Monitoring Full body opening Cake thickness sensor Nitrogen blanketing PLC Controlled Operations Residual Heel Removal |

|

Trolley Mounted Top Discharge Centrifuge / LaboratoryTrolley mounted machines are available from 12” dia to 36” dia with capacity ranging from 15 liters to 150 liters.Manual dome opening is available uptp 24” dia. Features : Easily movable between different operation areas. No grouting required. Recommended for clean House Keeping. |

|

Full Body Opening CentrifugesThe entire outer casing of centrifuges is opened with the help of hydraulic cylinder and the hinges on outer body.Advantages : Easy & quick access to Basket, Bottom trough and Inner Surface of Outer Case for quick and effective cleaning, inspection and validation. Quick change of filter media. Maintenance of shaft & bearing housing can be done easily. Very useful where frequent product changeovers and required. Clean-in Place : To prevent batch to batch contamination CIP is required and preferred in Pharmaceutical Industry. The nozzles are placed at strategic locations so that high pressure spray of water or solvent flush grind all the probable areas. |

|