|

DMW Centrifuges are the heavy duty Centrifuge with robust construction, provide rapid acceleration and smooth running. We at ‘DMW’ have experienced and qualified team of Engineers, which continuously make changes according to the latest technology, and customer needs to ensure customers satisfaction. Our machines consume less starting and running current and have powerful efficient braking.

|

|

Spindle Type for Cone / Cheese Drying

DMW Hydro Extractors are the heavy duty Centrifuge with robust construction, provide rapid acceleration and smooth running. |

|

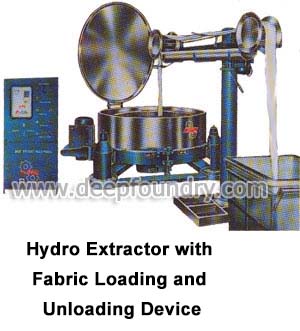

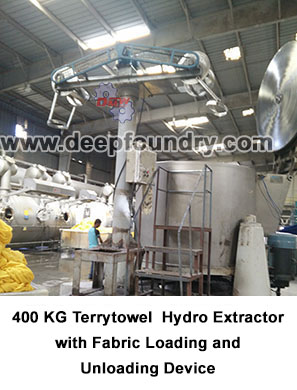

Hydro Extractor with Fabric Loading & Unloading Device

DMW introduces their latest ‘MASTER HYDRO EXTRACTOR’ with state of the art technology and advanced features for the utmost convenience of the Textile Processing House. This Machine with AC Inverter Drive and Fabric Loading / Un loading Device has innumerable advantages over the traditional Hydro Extractor.

|

|

Cake Lifting Hydro Extractor for Fibre / Loose StockCapacity :100 Kg to 500 Kg per batch. Sailent Features : The dyed fibre cake from HTHP Dyeing Machine is directly loaded into this cake lifting Hydro Extractor for Drying. After Drying this fibre cake is taken out along with SS dyeing plate. Simultaneour opening of both the lids for easy entry and exit of cake. PLC controlled panel for complete automation of drying cycle. |

|

Tow Carrier Lifting Hydro Extractor Machine

DMW has successfully launched carrier Lifting machine for Tow/ Fibre dyeing carrier from dyeing machine is directly loaded into Hydro Extractor for drying, hence saves a lot of time and labour.

|

|